9. Propositions for perspective project implementation of coal mining combines for work under the conditions of pitching, steeply pitching and steep coal seams:

1. Project of “КТНГ” combine for development of pitching and steeply pitching coal seams

At the present moment there is a steady demand for a coal mining equipment and technology under the conditions of steep (56 — 90°), steeply pitching (36 — 55°) and pitching (19 — 35°) bedding on the world market of mining equipment. Moreover, this demand has a sustainable tendency of growth because mining enterprises of deposits with more or less favourable conditions of coal seam bedding have greatly increased mining depth, which at the present day, has set the defined limit to the achieved level of mineral production mining technology. It is more difficult to ensure fair price of mining feedstock and sufficient mine safety level under the conditions of depths more than 1 km, increased gas content, danger of coal and rock outburst, substantial heat generation. Modern mining technology limitation has been clearly outlined at depths more than 1 km. Besides, mining enterprises with the above mentioned coal seam bedding conditions don’t receive effective support in solution of their technological tasks. Actually, it doesn’t exist as R&D works (research and development works) of this course were stopped in the middle of late 90s of previous century. However, at the present time situation on the mining equipment market changed towards increase of interest to mining equipment for coal production on pitching, steeply pitching and steep coal seams. It has become especially of immediate interest for some prospective markets of India and Indo-China.

All this, in general, has determined getting around to the earlier lost interest to mining works on pitching, steeply pitching and steep mineral product bedding. It concerns almost all capacity ranges of stratified deposits, including coal deposits.

The introduced for your attention project deals with coal deposit range from pitching to steep under the conditions of very thin (less than 0.7 m), thin (from 0.7 till 1.2 m) and average capacity (1.2 – 3.5 m) of coal seams for work by strike cutter loader faces.

Relevance of this project consists in necessity of assuring mine safety in the matter of development of so called “protective seams” providing henceforth an opportunity of development of the whole “protective” seam series using method of protective overworking and undermining. It is no secret that today the issue of coal and rock outburst prevention by recoverable coal extraction is of current importance for many deposits, in particular for Ukrainian Donbas. The only effective is extraction by technology of overworking or undermining with protective seams of the whole protective seam series combined with other manufacturing methods, for example, seismic prediction. As a rule, all protective seams are thin or very thin bed seams. There is especially pressing demand for such equipment in Ukraine, Russia and also on coal markets of the countries of the South America, India and Indo-China.

“КТНГ” coal mining combine model for work under conditions of thin pitching and steeply pitching coal seams has been worked out by our enterprise for satisfying the existing demand. We pursued the aim of machine creation that is in the most flexible way adjusted for work under the conditions of very thin pitching and steeply pitching bedding with capacity of being used on a heavy pitch. Within the objective to be achieved in the result of conducted exploration a new engineering solution (hereinafter referred to as “КТНГ” combine) has been discovered, which is protected with the proper patent at the moment.

This machine is offered for the change of available in operation “2КЦТГ” and “Kirovets-2K” combines (USSR-Ukraine manufactured). Peculiarity of “КТНГ” combine is a machine operation capacity on very thin pitching and steeply pitching coal seams with opportunity of carrying out works on “protective” seams. There is also an opportunity of combine operation by heavy pitch for work according to the adown underhand technology that is extremely potential area of combine implementation. The proposed construction has sufficiently wide range of application and can be in demand on all available markets of mining equipment working for steep, steeply pitching and pitching bedding.

Extra feature of the machine is an opportunity of its implementation on the very thin flat-lying seams, where almost there is no opportunity to use power driven complexes. This offer can resonate with the so called, “small” private mines, where manual work is popular to a large extent.

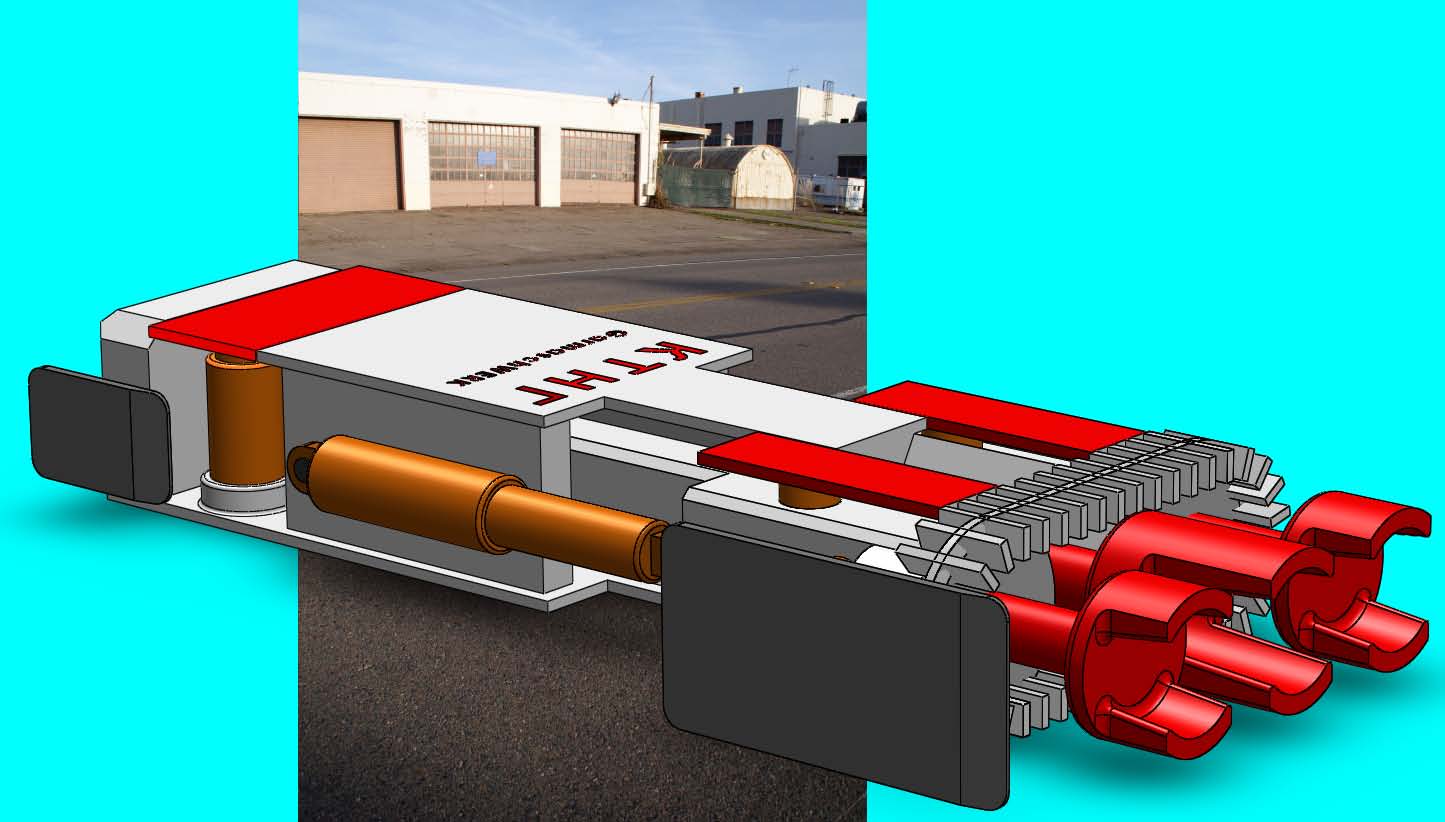

Figure 1. Possible execution of “КТНГ” combine (sketch).

General view of possible combine execution is shown on Figure 1.

Area of application: “КТНГ” combine (К — combine, Т – for thin seams, Н – for pitching seam bedding, Г – with hydraulic walking and stabilizing feed system). It is designed for coal extraction in mining faces, moving along the strike with capacity (0.55-0.75) m (I – standard size: (0.55 – 0.6)m; II – standard size: (0.6 – 0.68) m; III – standard size – (0.68 – 0.75)m), with fall angles from 19° till 55° with coal cuttability up to 300 kN/m. The combine can be used in seams with unstable roof and floor. Herewith, it is obligatory to finish each extraction cycle (feed step of walking spacer stabilizing system) with permanent breast timbering installation. Combine use on outburst-prone seams and on coals apt to spontaneous inflammation, increased gas content and presence of dangerous in frictional relation inclusions, should be agreed in each certain case with the national mine safety controlling body.

Operation scheme: The combine works according to a one-sided scheme adown in-web with additional protecting winch of 3ЛП and 1ЛГКНМ1Э type, work according to a two-sided scheme with 180°-turn along longwall edges is acceptable (fall angles from 19° to 35°). A one-sided or two-sided scheme of work is considered acceptable on a flat pitch (from 0° to 18°) in the seam thicknesses corresponding to standard size combined with conveyors of СП46, СК38, СР52 type and other similar types. The combine is used with individual timbering in all mentioned ranges. The main area of application with pitching and steeply pitching seam bedding provides basically work with inclines and slides, grates reinforced by metal plates (without face conveyor). While working according to a one-sided scheme adown pitching and steeply pitching seam bedding machine is returned to a normal position to a new machinery runway using additional protecting winch. Machine adjustment to a new machine runway is made from prearranged niche. It’s acceptable to carry out heat (approach) of machine to a new machine runway without niche from the exposed side of prepared roadway (gateway) while providing conditions of arching and stabilization of hydraulic walking anchor system of the combine. The machine performs coal extraction cyclically due to its own hydraulic feed system after termination of cycle of arching and fixation of machine frame regarding a working face and side rocks. Basic characteristics of the project are given in the table 1.

Our enterprise has developed the corresponding business-plan of partial R&D execution with the corresponding approximate calculation of the necessary financial expenses wherefore a financial investor with a technological base for practical project implementation is being searched for.

Interested people can receive additional information getting in touch with us using the above mentioned e-mails.

Basic preliminary technical characteristics of “КТНГ” combine are given in table 1.

Table 1. Basic technical characteristics of “КТНГ” combine (preliminary).

| Executor height, mm | 500, 550, 625 |

| Design capacity, t/min | not less than 0.5 |

| Width of usable executor cut, m | 1.55 – 1.6, (2) |

| Supply voltage, V | 660 |

| Capacity of the main cut engine, kW | up to 90 |

| Combine weight, t | up to 9 |

2. Project of “KOBOLD” combine for development of thin steeply pitching and steep coal seams

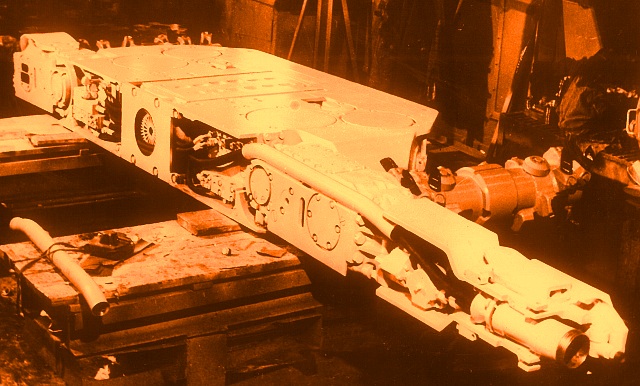

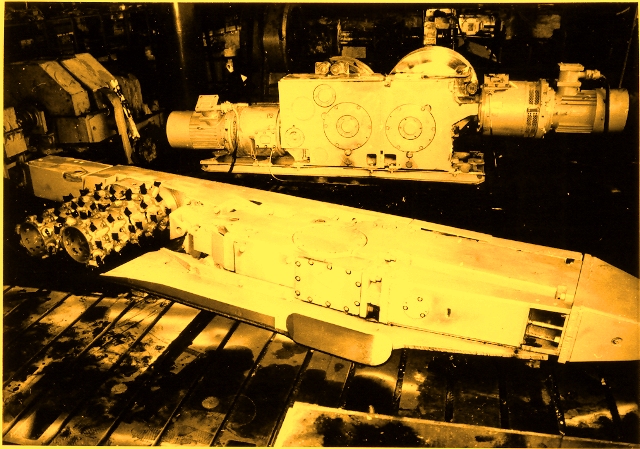

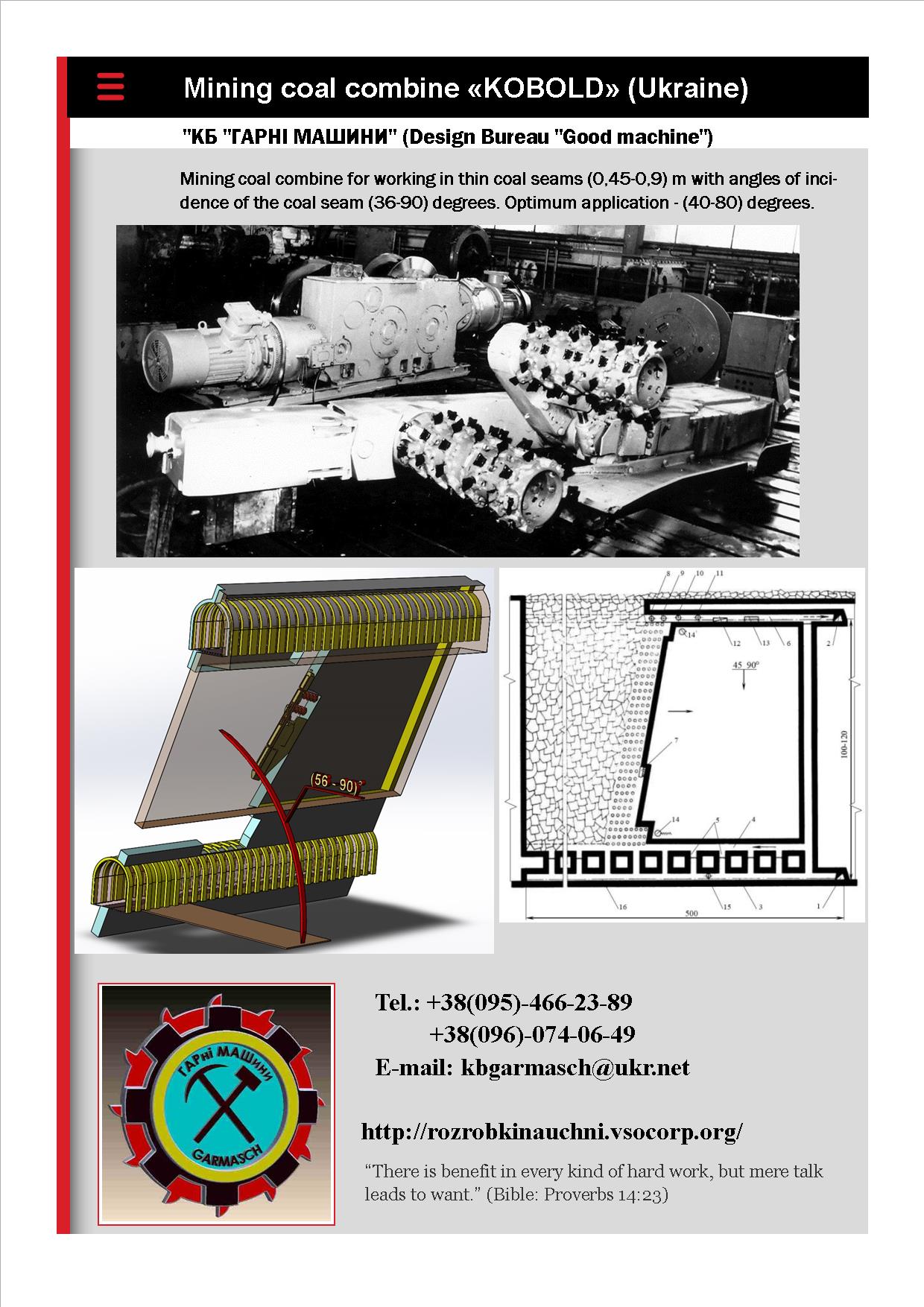

In the beginning of 90 s of the previous century in Ukraine two perspective models of cutter-loaders were tested for works under the conditions of steeply pitching and steep coal seams bedding according to standard size КУ 4. One of it was called “Universal-90”. At the present time this development doesn’t correspond to modern requirements of frictional safety. Production of some important electric arrangements for this machine was also lost. Many useful constructive solutions were completed on this combine and it makes sense to use it in future. The machine was purposely designed as a module construction for implementation of all typical compositions of executors with horizontal cutting drum. Our bureau analyzed an arrangement opportunity of cutter-loader of КУ 4 with vertical cutting drum for working conditions in a steep pitch. Good enough results were received in a stability analysis. Some combine data according to construction of “Universal-90” type are the given below. This combine is “KOBOLD”.

The machine is meant for coal extraction in mining faces (longwalls), developed according to outstretch of steep and steeply pitching seams of capacity (0.45 – 0.9) m with fall angle more than 35º (optimal implementation 40º-80º) and cuttability up to 300 kN/m with side rock not less than of mean stability (while working according to a one-sided scheme adown to buttock without special machinery runway). There is an opportunity to operate using a gateway.

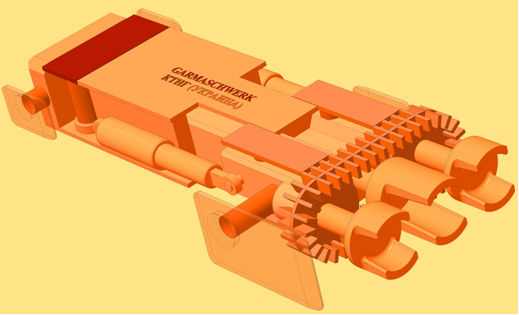

“KOBOLD” project has two arrangement opportunities: with horizontal cutting drums (“Universal-90” combine scheme) and with vertical cutting drum. Figure 2 shows arrangement with horizontal contiguous cutting drums by the scheme of “Universal-90” combine for work seam floor. The combine has electric and pneumatic execution for work on protective seams. The machine is completed for work from seam floor and complex rigid wheel base. There is an opportunity of arrangement with 100, 120 kW air-cooled motors. Base construction provides implementation of special explosion-proof electric induction motor for cutter-loaders used on steep and steeply pitching of ЭДК 3.5-90 type.

This combine is designated for a full-fledged replacement of shearers of “POISK-2Р” and “POISK-3” type. The machine can also find a widespread application for work both on protective seams and protected seams. Our agency can recreate the set of construction documentation of this complex with the aim of production renewal of the necessary specific electrical equipment.

Our enterprise has designed the corresponding business plan of phased execution of R&D with corresponding approximate calculation of the necessary financial expenses wherefore a financial investor with a technological base for practical project implementation is being searched for.

Interested people can receive additional information getting in touch with us using the above mentioned e-mails.

Some basic technical performances of combine “KOBOLD” are given in table 2.

Figure 2. Prototype of “Kobold” combine with horizontal cutting drums (“Universal-90”)

Table 2. Technical characteristics of “KOBOLD” combine

| Capacity (depending on seam power and cuttability), t/min | 1.1-1.5 |

| Limits of executor height control, mm:

lower upper |

430 900 |

| Nominal executor grasp width, mm | 900 |

| Upper limit of infinite speed control, m/min:

Electric version Pneumatic version |

4.5 – |

| Total nominal drive capacity, kW: | 150 |

| Combine dimensions, mm:

length width combine body height |

5200 1300 350 |

| Combine weight, kg:

Electric weight Pneumatic version |

5500 5600 |

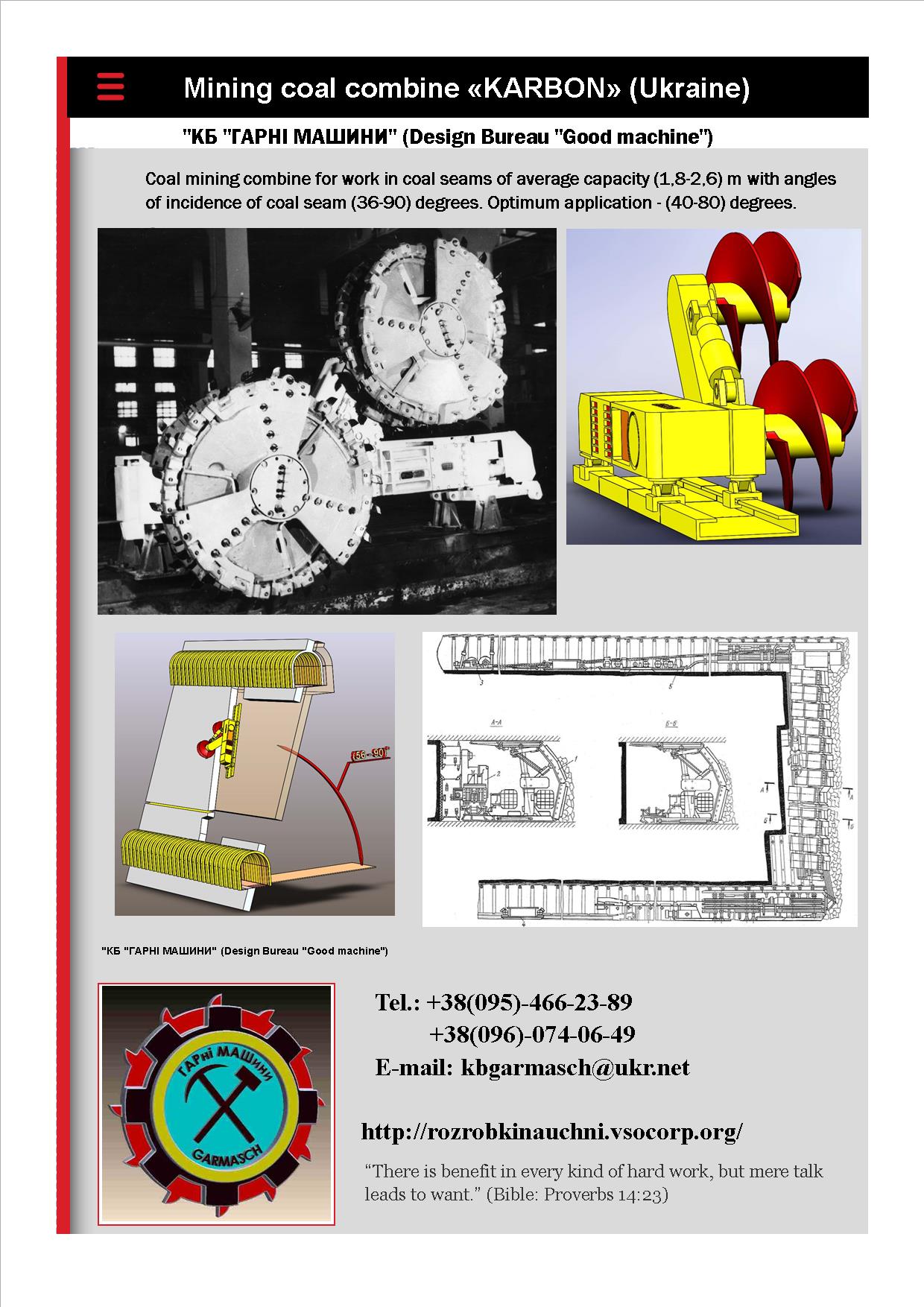

3. Project of “KARBON” combine for development of average power of pitching and steep coal seams

For a long time it was considered that no shearers were created for steep and pitching coal seam bedding of average power. It is a profound mistake, because the sphere of mining equipment for the mentioned mining and geological conditions was never highlighted properly in technical literature, though the corresponding works were held, and quite successfully. In the late 80ies of the last century ДКР shearer was created in Ukraine for operation as a part of complex КПК 1 of Russian manufacture. The machine has passed the whole set of industrial tests and showed excellent results. However it didn’t go into production because of lobbying the АK-3 winning assembly project in the Ministry of mining industry of the former USSR. As a result both machines were buried in bureaucratic procedures of monetary fund distribution and search of producer. Our bureau offers modernized version of ДКР combine called “KARBON”.

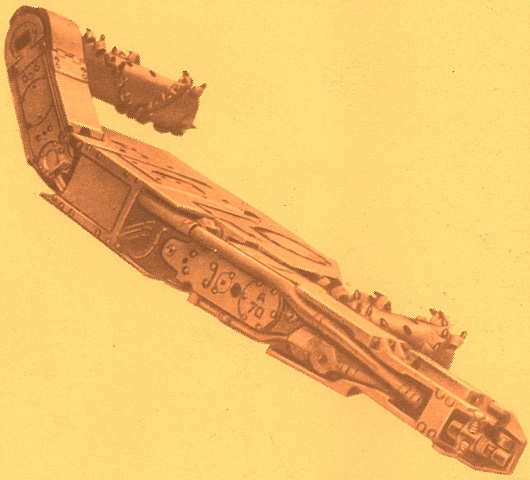

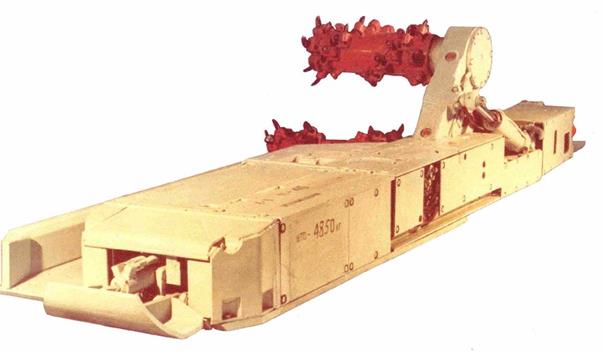

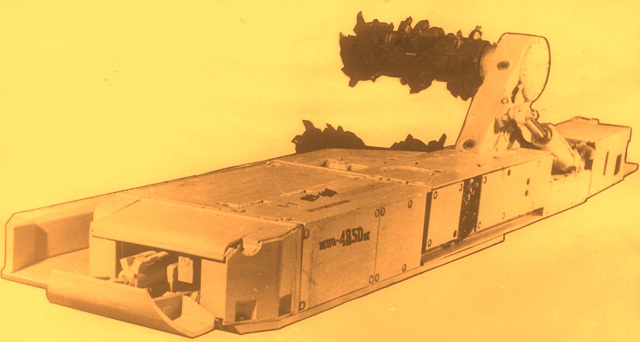

“KARBON” combine is designed for a mechanized coal extraction from seams with dip angle over 35º (with coal gravity drop) and work in kinematic connection with shield supports (КПК 1 type), moving along the strike, cable system of feed ЛГК, safety winches and chain cable handler. Combine is designed for operation by one-way pattern from bottom to up with self-cut in seam in any face part. Outer appearance of prototype is given on Figure 3. Characteristics of operation conditions is given in Table 3. Short characteristics of basic model of the combine with horizontal cutting elements is given in table 4.

Our enterprise has developed the corresponding business-plan of stepwise R&D execution with the corresponding approximate calculation of the necessary financial expenses, wherefore a financial investor with a technological base for practical project implementation is being searched for. Individual offer – project of “Karbon” complex of shield support analogue КПК 1.

Interested people can receive additional information getting in touch with us using the above mentioned e-mails.

Figure 3. Prototype of “KARBON” combine ДКР combine

Table 3. Operation conditions of “KARBON” combine

| Mining face length, m, not more | 100 |

| Extracting seam thickness, m

(for support of КПК 1 type) |

1.8 – 3.2 1.8 – 2.6 |

| Seam inclination, …º | 35 – 90 |

| Roof and soil stability | Up to unstable |

| Admitted roof outcrop during 20 min, m2 | 3.5 – 6 |

| Admitted curve radius of seam soil surface, m, not less | 30 |

| Roof support and control | Full collapse |

| Coal hardness coefficient by Prof. Protodyakonov scale, not more | 3 |

| Coal cuttability, kN/m (kgsec/sm), not more | 300 (300) |

| Hardness coefficient of dirt bands by Prof. Protodyakonov scale, not more | 3 – 4 |

| Admitted total dirt bands capacity from seam extraction height, %, not more | 12 |

| Mine category by gas or dust | any |

| Seams danger by sudden rush and rock outbursts | Not dangerous, protected with overworking or underworking |

Table 4. Technical characteristics of “KARBON” combine

| Capacity (calculated for average operation conditions), t/min | 8 |

| Average daily production, t | 1020 |

| Limits of executor height control, mm:

lower upper |

1600 2600 (3200) |

| Nominal grasp width of executor, mm | 630 |

| Upper limit of infinite speed control, m/min: | 7,5 |

| Total nominal drive capacity, kW: | 160 (200) |

| Combine dimensions, mm:

length width combine body height in support zone |

4200

1530 1230 |

| Combine weight, kg: | 10800 |

| Feed gearing – ЛГК system

Total feed system draft force, kN (tf) Protective winch Haulage winch |

245 (24,5) 45 (4.5) 200 (20) |

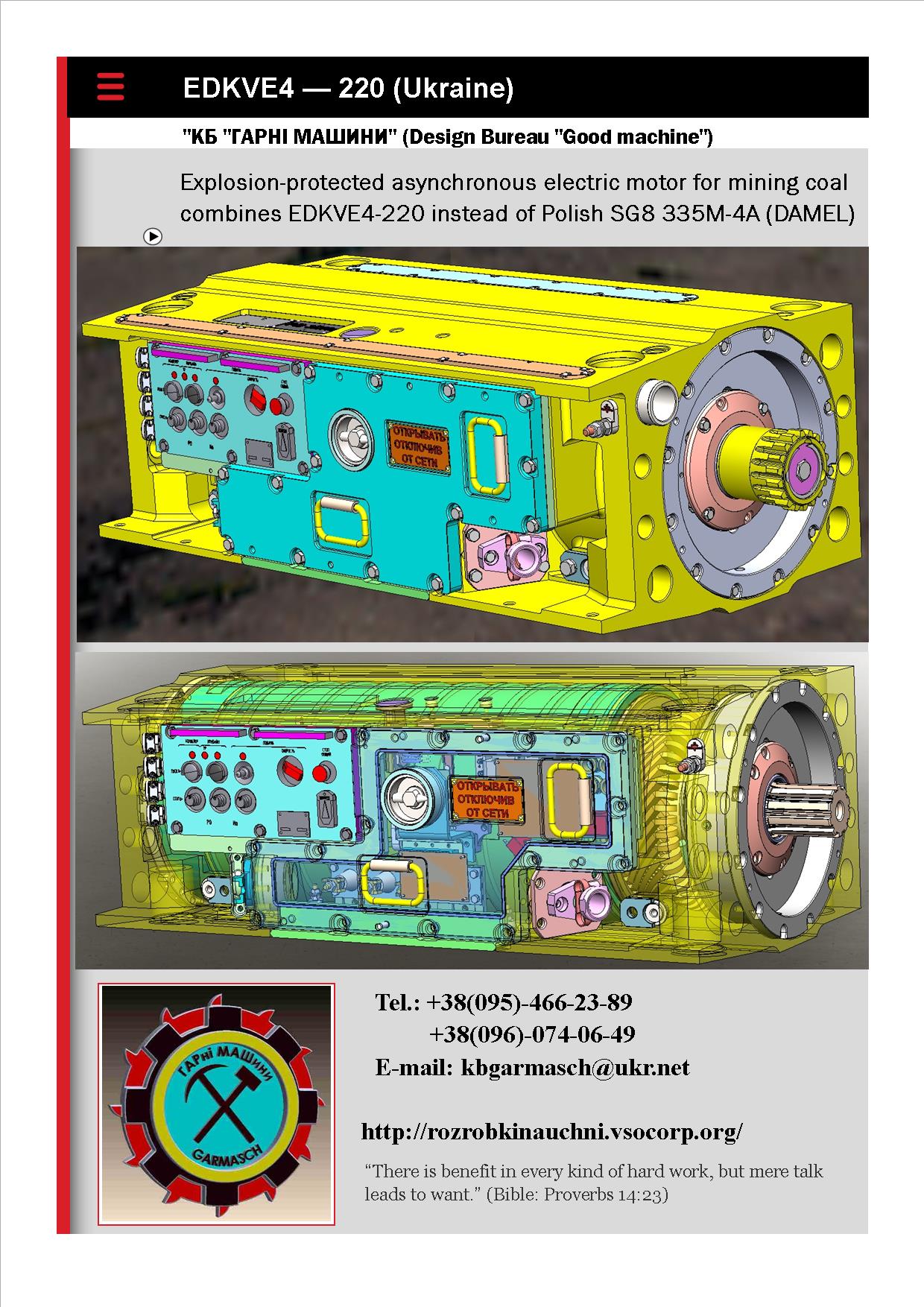

4. Project of special combine electric motor ЭДК 3.5-90 for combines working on steeply pitching and steep coal seams

Separate direction of mining electric technique is electric equipment for work under conditions of pitching, steeply pitching and steep coal seams in mines which are dangerous because of coal and rock outburst, inrush and gas. It is generally said that a pneumatic drive should be used in such conditions, in other words, combine should have hardware version with pneumatic motor. Specified statement is true, but only for work on separate outburst-prone open coal seam. For example, for the very such conditions in due time the combine version A70 of standard size КУ 4, represented on figure 4, was designed. Herewith the single-valued solution of the national controlling body in mining operations safety is necessary for solution about exceptional use of pneumatic drive.

However, in the overwhelming majority of cases the electric drive can and should be widely used. For this purpose under the USSR the special types of local transformer substations and low voltage equipment were designed. Combine electric motors were always the special type of electric machines in this set. Gathered experience of mining works showed, that electric motors of very high capacity as well as water-cooled motors were not necessary for work on steep and steeply pitching dip.

For example, results of direct measures of cutting motor consume power on the combine “Universal-90” showed, that cutting motor consumed no more than 30 kW power. Generally 15 – 20 kW power and even less. Herewith cable delivery system was never overloaded. However, one condition was always marked everywhere. Only motors of ЭДК and ЭДКО types were persistent and reliable. They developed enough power and were simple in operation. Thus, electric asynchronous explosion-proof induction combine motors with natural air cooling system and ventilated ones showed their exceptional reliability.

Figure 4. Combine А70 of standard size КУ 4 with pneumatic drive

For example, combine A-70M with motor ЭДК 3.5-40У5, represented on figure 5, showed excellent results.

Figure 5. Combine А70М of standard size КУ 4 with electric drive on the basis of motor ЭДК 3.5-40У5

Usage of combine water-cooled motors of ЭКВ type on steep dip always finished unsuccessfully. Thus, an effort to excel indexes of A70M on combines of set “POISK-2” and “POISK-3” led to the fact, that big quantity of broken machines became collected in mines. Low proficiency of working personnel and operation aspect of steep dip worsened the situation. For the reason that roof caving does not happen or happens very slowly in conditions of steep and steeply pitching position and is not on all square, water penetrates from one mining level to other, becoming a real disaster. That is why mining operations are held without spraying and correspondingly without motor cooling. Of course, that is wrong. But that is reality. That particular fact enforced to return to motors of ЭДК and ЭДКО types at the beginning of 90-s of previous century. In such a way the special combine electric motor for steep dip machines ЭДК 3.5-90 appeared.

All last projects of combines for steep and steeply pitching seams extraction of standard size КУ 4 were with motors of ЭДК type. These projects are represented on figures 6 and 7. These are combines “Universal-90” and “КУ-410”.

Now nobody produces the motor ЭДК 3.5-90 officially. However, our bureau is able to reconstruct necessary construction documentation for production of its modernized analogue. It is quite difficult to design reliable combine for steep and steeply pitching seams extraction of standard size КУ 4 without this electric motor, more precisely – impossible.

Figure 6. Combine “Universal-90” with motor ЭДК 3.5-90

Figure 7. Combine «КУ-410» with motor ЭДК 3.5-90

Some design performances of one of the ЭДК 3.5-90 versions are given in table 5.

Table 5. Fragment of technical performances of ЭДК 3.5-90

| Electric motor type: | ЭДК 3.5-90 |

| Working mode: | S2-60 min |

| Capacity, kW: | 90 |

| Nominal current In, А: | 126.4 |

| Efficiency coefficient: | 92 |

| cosφ | 0.894 |

| S1, % | 2.6 |

| n1, (synchronous frequency – rev/min) | 1500 |

| Мstart , Н·м: | 1334 |

| Мmax , Н·м: | 1488 |

| Мstart/Мnom: | 2.3 |

| Мmax/Мnom: | 2.5 |

Our enterprise has designed the corresponding business plan of phased execution of R&D with corresponding approximate calculation of necessary financial expenses, wherefore a financial investor with a technological base for practical project implementation is being searched for.

Interested persons can receive additional information getting in touch with us using the above mentioned e-mails.

With other equal conditions, implementation of the Project “Combine “КТНГ” is priority direction of cooperation for our bureau regarding creation of coal mining combines for work in conditions of pitching, steeply pitching and steep coal seams.

E-mail:

kbgarmasch@ukr.net

tel: ![]() +38-095-466-23-89

+38-095-466-23-89

![]() +38-096-074-06-49

+38-096-074-06-49

.jpg)

Что говорят люди?