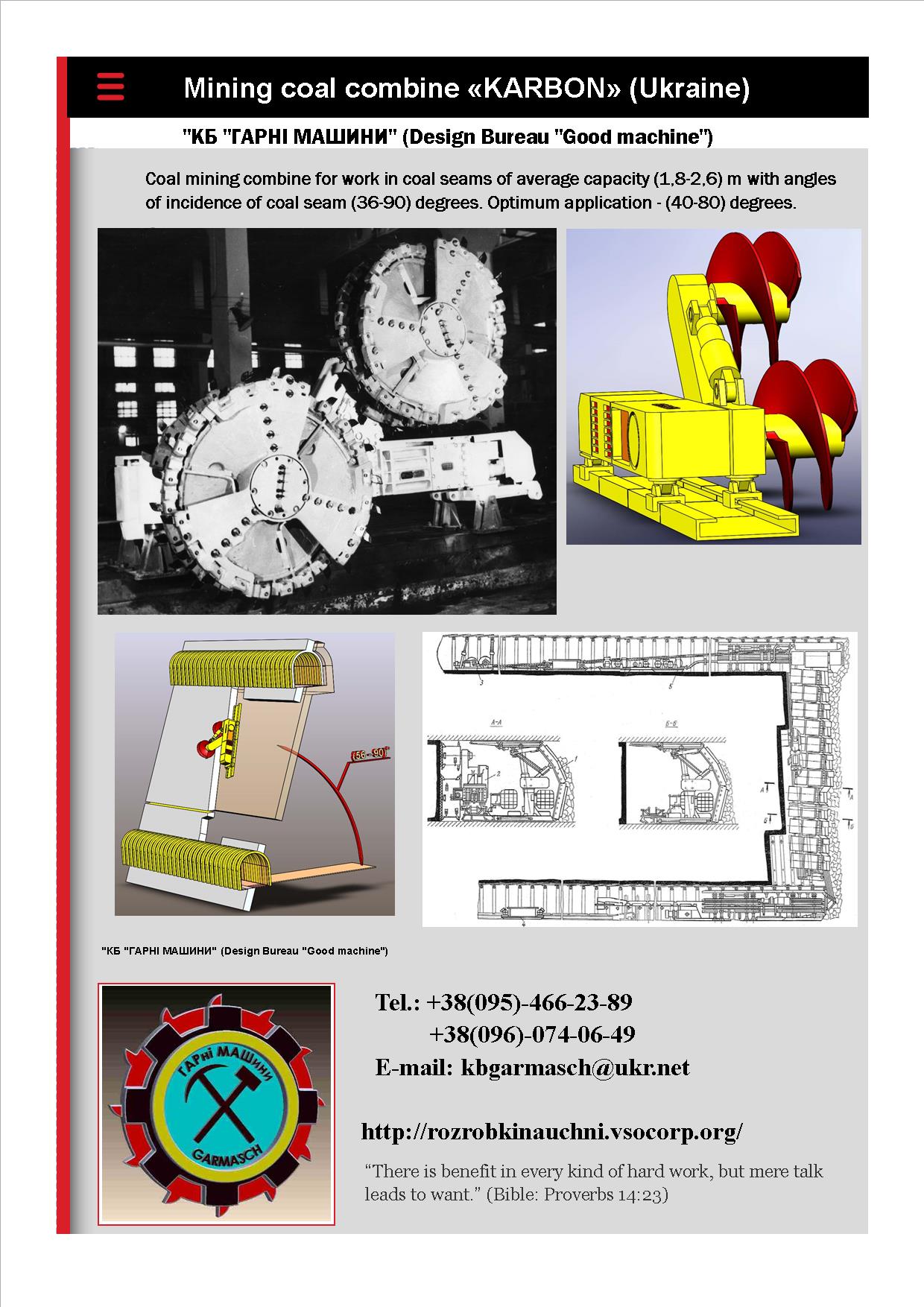

MINING MASHINE: Cutter-loader coal combine «KARBON»

Designed for coal winning from production faces worked on the strike of steep and steep-inclined seams, 1,8-2,6 m thick, with a dip angle exceeding 35° (optimal 40°-80°), and coal resistance to cutting of up to 300 kN/m. The combine can be controlled from a drift.

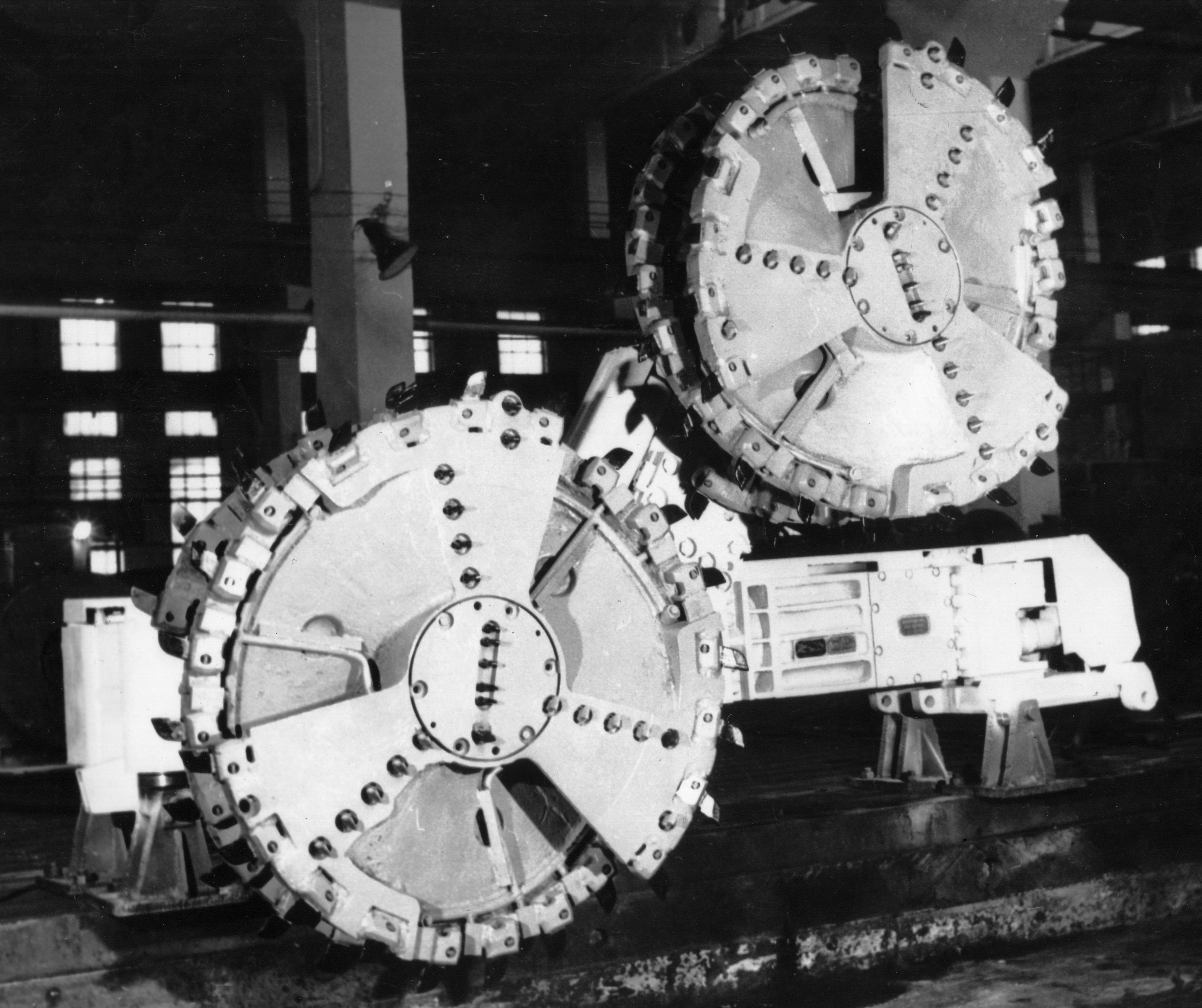

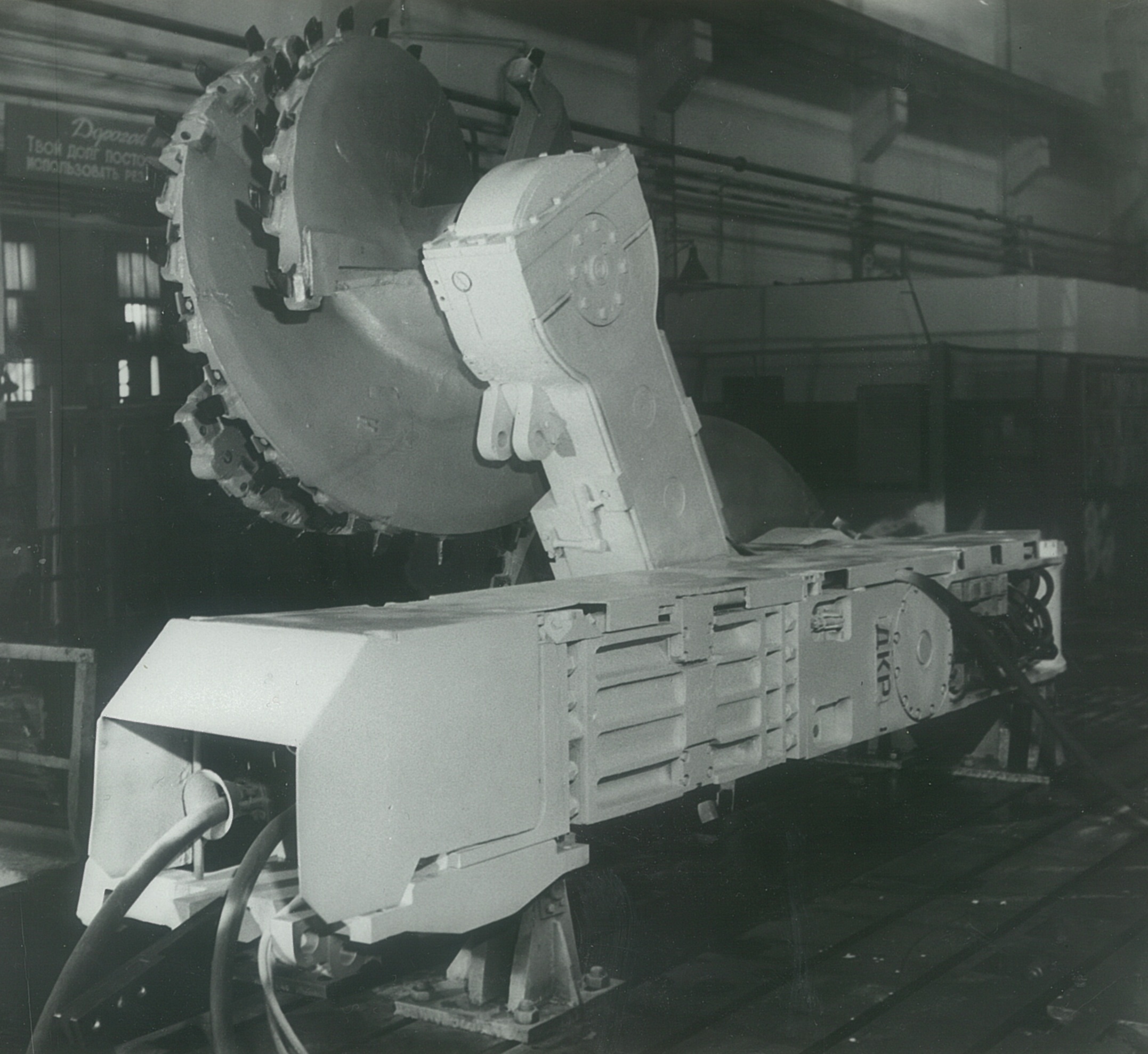

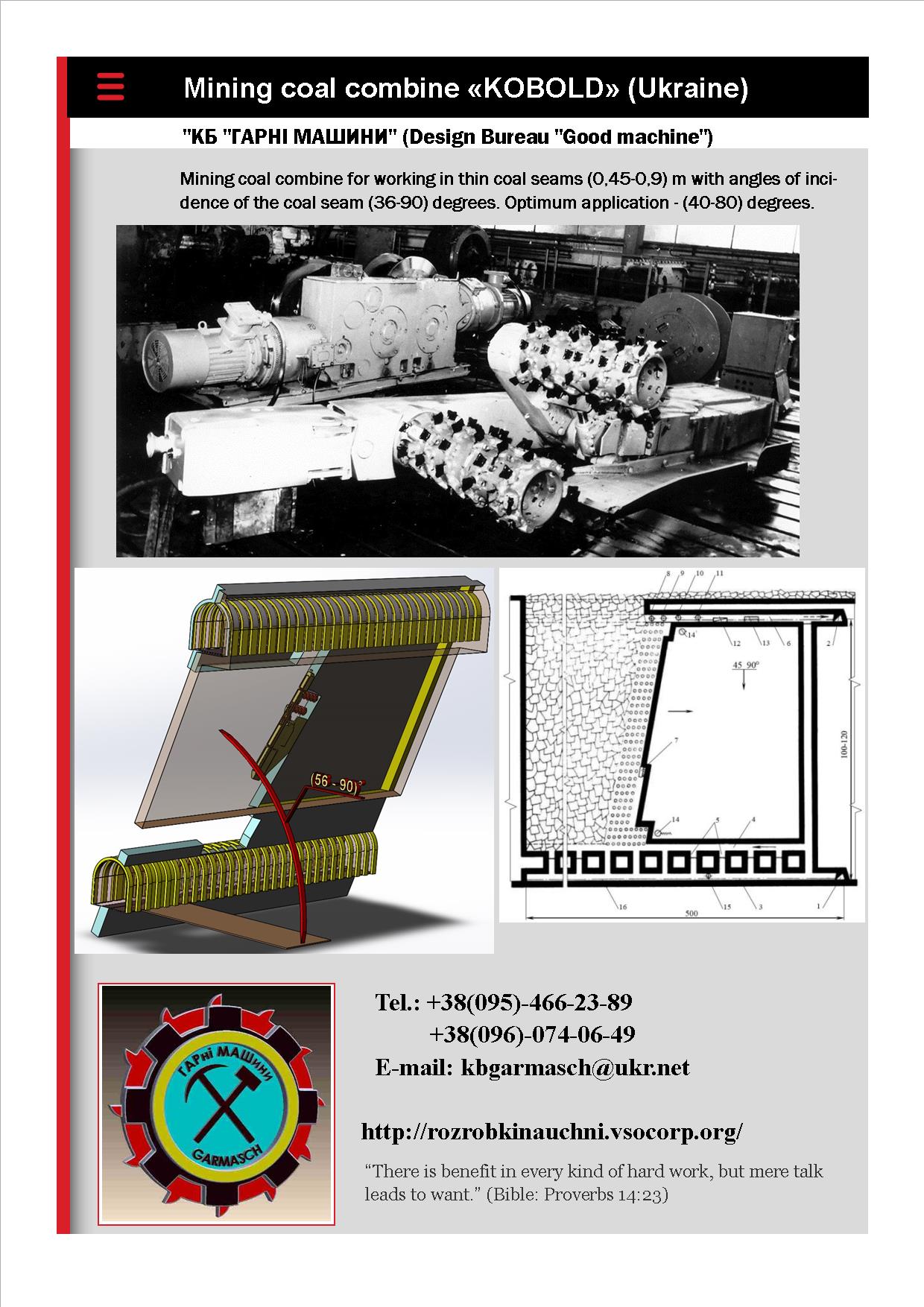

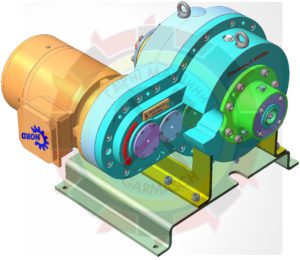

Drawing A. The combine «KARBON» prototype (combine «ДКР»)

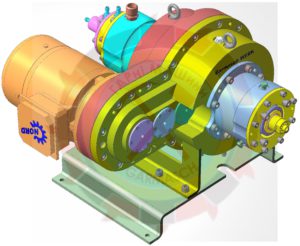

Drawing B. The combine «KARBON» prototype (combine «ДКР»)

Drawing B. The combine «KARBON» prototype (combine «ДКР»)

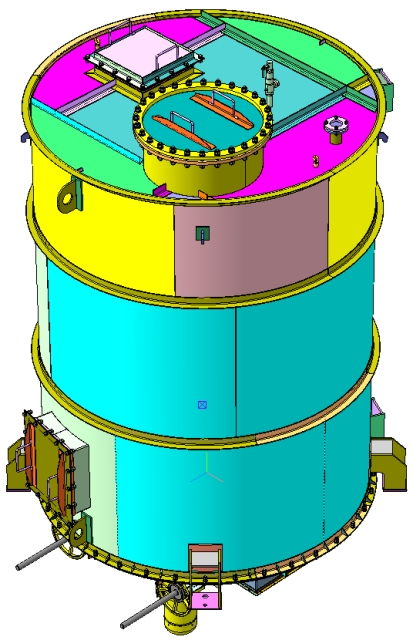

COMPLEX «Karbon» powered support:

Intended for mechanization of supporting, controlling and quarding the working area from penetration of qob rock in coal seams, 1,8-2,6 m thick, at dip angles of over 35° with the stable and caving coals and the wall rocs of not lower than medium stability including the seams where zones of unstable (insecure) wall rocs are periodically found. The slope angle of support front relative to the line of dip is 3-9 degrees.

It consists of ends-making and line sections of the same type moved to the strike of a seam and operates together with a stoping narrow-cut combine of the «KARBON».

The modernized support as distinct from the «КПК-1М» standart support has the following features:

— section resistance, telescoping, slope angle of support front relatively the line of dip are increased;

— the necessity of goaf fence remounting when passing into anothe face is liquidated;

— slip joints of hoses are used;

— working pressure of hydraulic system is increased;

— in the construction of goaf fence the elements increasing pitching section stability are inserted;

— the system of dust suppression which suppresses dust at goaf when transdering section is introduced.

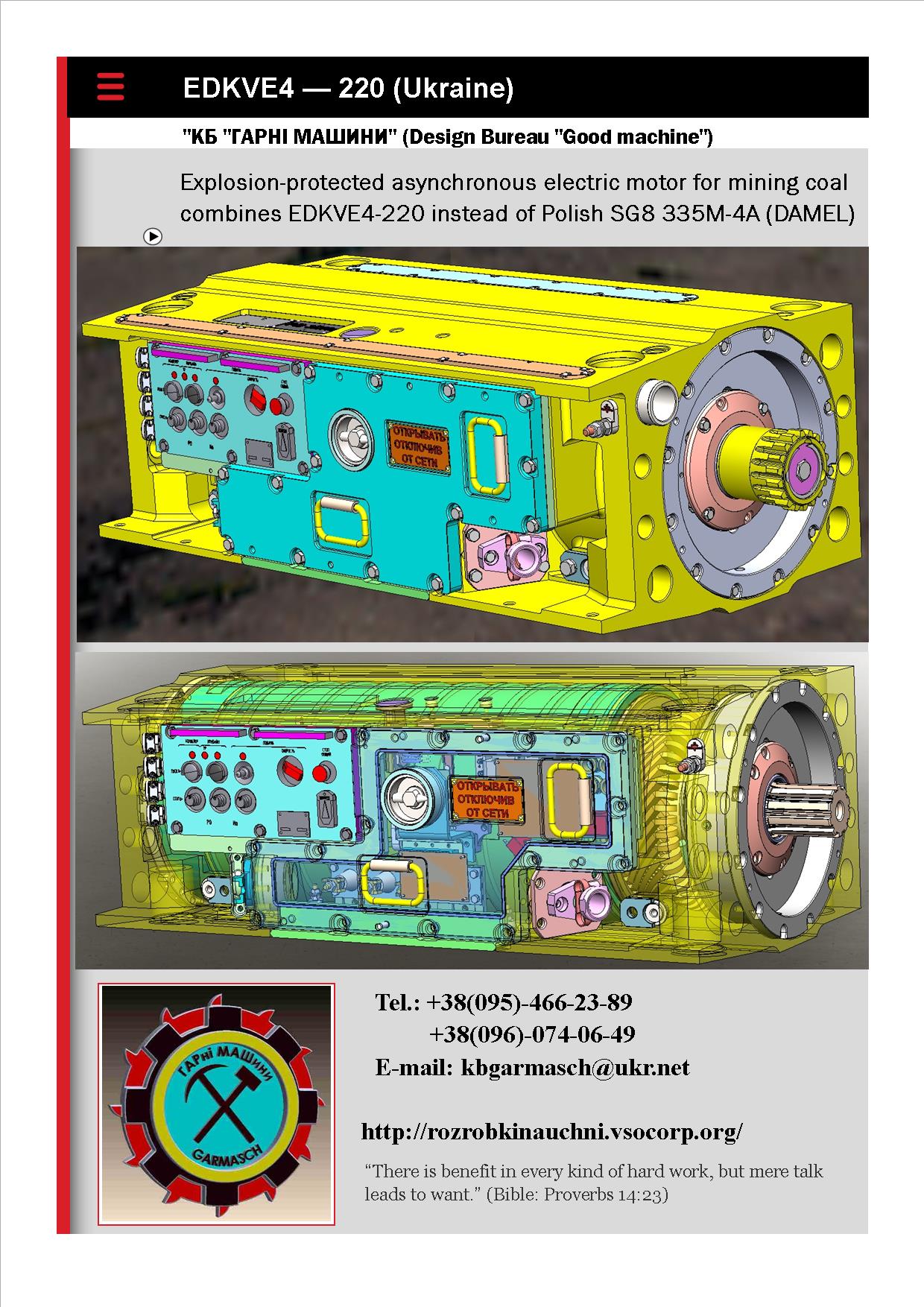

We offer working out of a cutting loading machine and the services in designing of the mining equipment.

E-mail:

kbgarmasch@ukr.net

tel: +38-095-466-23-89

+38-096-074-06-49

Diplomaed mining mechanical engineer Garmash Oleg.

.jpg)

Что говорят люди?